Dental 3D printing is a strategic necessity, enabling high-volume production of models, guides, and temporaries with unmatched accuracy, material versatility, and speed.

The digital revolution has completely changed the way dental products are made. At the forefront of this change is dental 3D printing technology, which is also called Additive Manufacturing (AM). Modern 3D printing systems give labs and clinics that are ahead of the curve a level of design freedom, customization, and material versatility that traditional subtractive and analog methods can’t match. Investing in a complex 3D printing ecosystem is a smart move that expands the range of services offered, makes workflows more efficient, and greatly improves the quality of devices made for individual patients.

Adding Advanced 3D Printing Applications to your Services

The most convincing reason to use 3D printing is that it can make a wide range of clinical tools from a single, integrated digital workflow. The technology used to only make basic models, but now it can reliably make final and interim devices for almost every dental specialty. This flexibility lets a lab combine production and have more control over quality and turnaround time.

Some of the most important uses for dental additive manufacturing are:

- Models for Thermoforming: Making very precise models for making clear aligners and retainers on a large scale.

- Surgical Guides: Making guides that fit perfectly and are safe for the body for placing implants, which leads to predictable and minimally invasive surgical outcomes.

- Custom Trays and Bases: Quickly making personalized impression trays and denture bases that fit better and make patients more comfortable.

- Restorative Mock-ups and Temporaries: Printing of very beautiful temporary restorations, crowns, and bridges so that doctors can check the fit and look before they make the final product.

- Splints and Night Guards: Making occlusal guards and splints that are strong, comfortable, and fit perfectly with complicated geometric shapes.

Call Axsys Dental Solutions today at (855) 687 7941 for more information!

Improved Accuracy and Speed

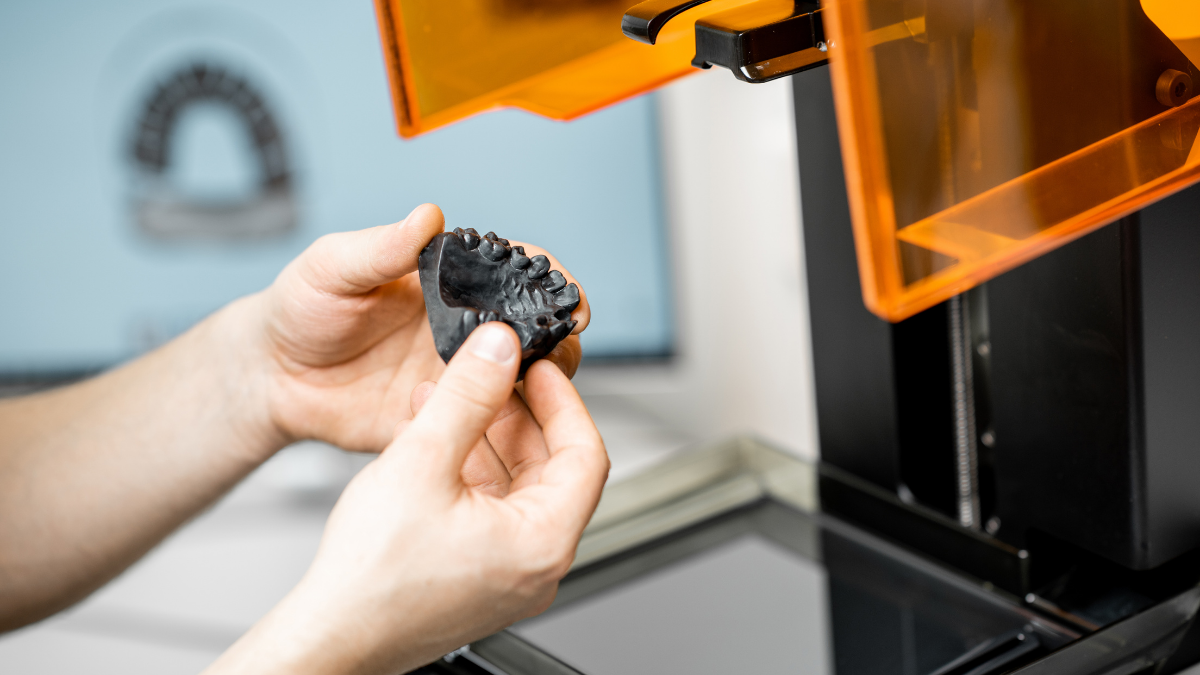

Dental 3D printing makes things by adding layers on top of each other. It mostly uses high-resolution stereolithography (SLA) or Digital Light Processing (DLP) technologies. This additive process is made to reproduce complex CAD designs with high fidelity. The output is more detailed, accurate, and consistent than what you would get from traditional casting or manual fabrication.

Modern 3D printing systems are very accurate, so appliances fit exactly as planned. This means fewer adjustments at the chair and less time spent on treatment overall. Also, the ability to batch-print multiple devices in one job greatly increases throughput, which means the lab can handle a lot more cases without having to hire more people, which lowers the cost per part and maximizes profit.

The Strength of 3D Printing Resins That Are Biocompatible

The ongoing development of certified, biocompatible 3D printing resins is what really makes 3D printing more flexible. Manufacturers have made special resins for almost every clinical use, making sure they are safe, long-lasting, and look good. The lab can confidently meet specific clinical and regulatory needs because it has access to a wide range of materials, such as rigid resins for surgical guides, flexible resins for occlusal splints, and resins that look natural for denture bases. This material’s flexibility is a key part of the additive manufacturing advantage because it gives you a tool for every situation.

Did you know?

that using 3D-printed surgical guides to place dental implants can make drilling up to ten times more accurate than doing it by hand? This greatly lowers the risk of problems.

A Smart Investment for Future Growth

Dental 3D printing systems are a must-have strategic investment in an industry where demand for personalized service and quick delivery is growing. They offer a complete way to manage many product lines with unmatched speed and accuracy, putting a lab in a position to lead the market.

Contact the digital manufacturing experts at Axsys Dental Solutions today at (855) 687 7941!

Frequently Asked Questions (FAQs)

Is 3D printing replacing milling in dentistry?

No. 3D printing (additive) and milling (subtractive) are complementary technologies. Printing is ideal for appliances, guides, and models (polymer-based), while milling is superior for final restorations like high-strength zirconia and glass-ceramics. A modern lab leverages both for a complete digital workflow.

How does 3D printing improve the clear aligner workflow?

3D printing enables the rapid, high-volume, and accurate production of sequential thermoforming models from a single digital file, dramatically accelerating the manufacturing phase of a clear aligner case compared to traditional model fabrication.