- Customer Care | Need help? Call us: (855) 687 7941

Menu

Close

- Home

- Products & Services

Company

The Axsys Advantage

Financing & Promotions

News & Testimonials

Product Portfolio

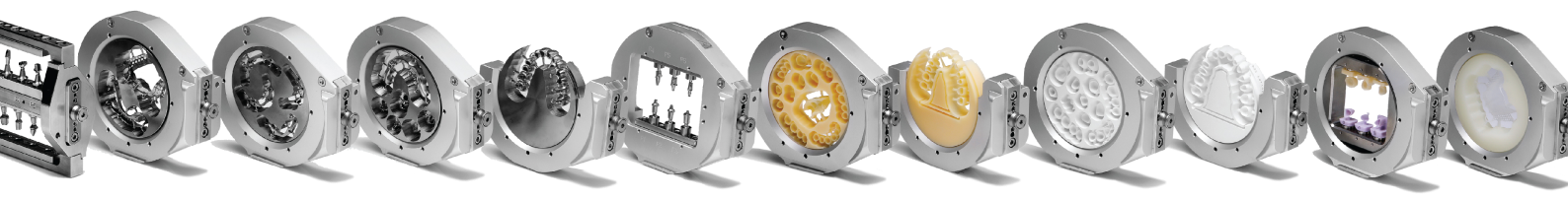

Dental Machining Centers

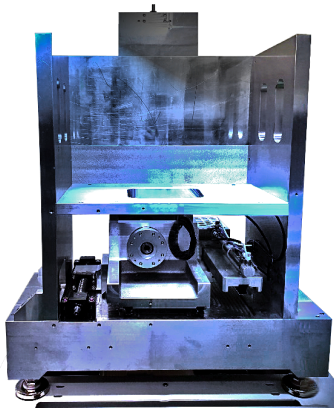

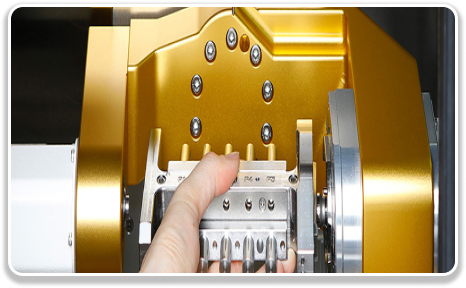

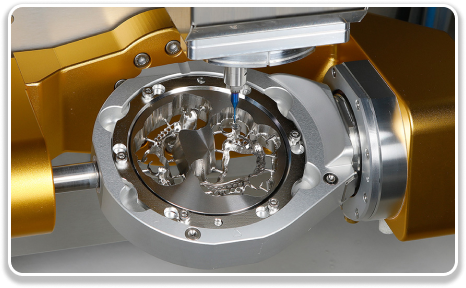

VERSAMILL CLASSIC COLLECTION

VERSAMILL SPEED COLLECTION 3 SERIES

VERSAMILL SPEED COLLECTION 7 SERIES

VERSAMILL SIGNATURE COLLECTION

Chairside Machining Centers

Consumable Products

- LEARNING ZONE

- Testimonials

- Blog

- Contact Us

- Home

- Products & Services

Company

The Axsys Advantage

Financing & Promotions

News & Testimonials

Product Portfolio

Dental Machining Centers

VERSAMILL CLASSIC COLLECTION

VERSAMILL SPEED COLLECTION 3 SERIES

VERSAMILL SPEED COLLECTION 7 SERIES

VERSAMILL SIGNATURE COLLECTION

Chairside Machining Centers

Consumable Products

- LEARNING ZONE

- Testimonials

- Blog

- Contact Us