Advanced dental milling machines are essential: they provide automated efficiency for high volume, deliver micrometer accuracy for fit, and expand material processing versatility.

The modern dental lab works in a very competitive and demanding setting where speed and uncompromising quality are the keys to success. The most important thing that can be done to solve these problems, boost laboratory output, and set new standards for restorative excellence is to use advanced dental milling machines. These Computer-Aided Manufacturing (CAM) tools are the most important part of the digital workflow. They turn complicated CAD designs into real, high-precision restorations with a level of consistency and speed that manual processes can’t match. Labs that want to increase production, handle a wide range of materials, and make more money need to invest in this technology. It’s no longer a luxury; it’s a strategic need.

Automated Efficiency for Dental Prosthetics in Large Quantities

The biggest and most immediate benefit of adding a dental milling machine is that it greatly boosts automated efficiency and capacity. Traditional methods of making things by hand take a lot of time, work, and are subject to human error. A high-speed, multi-axis milling machine and a digital workflow automate the subtractive manufacturing process. This lets labs make several units at once, 24 hours a day, 7 days a week.

This automation lets highly skilled dental technicians stop doing the same tasks over and over again, so they can focus on more important things like designing complex cases, final characterization, and quality control. A milling machine’s steady, consistent output removes the human bottleneck in production, making sure that deadlines are met and turnaround times are cut in half. This is true whether you’re making single crowns, multi-unit bridges, or complex implant frameworks.

Call Axsys Dental Solutions at (855) 687 7941 today to learn more!

Unmatched Accuracy for a Better Marginal Fit

The clinical success of any dental restoration depends on how well it fits, especially at the marginal interface. Advanced dental milling technology provides micrometer-level precision that is nearly unattainable via waxing and casting techniques. The machine’s axis configuration, which is usually 5-axis systems, makes this higher level of accuracy possible by letting the milling tool get to the restoration from many different angles.

This ability is very important for accurately milling complicated shapes, like deep undercuts and precise internal implant geometries, so that the implant fits perfectly on the prepared abutment. The better marginal fit means that the dentist doesn’t have to make as many adjustments at the chair, which saves time in the clinic. Most importantly, it makes the final restoration last longer and work better with the body’s natural processes, which saves the lab money on expensive remakes.

Processing Dental Materials in a Variety of Ways

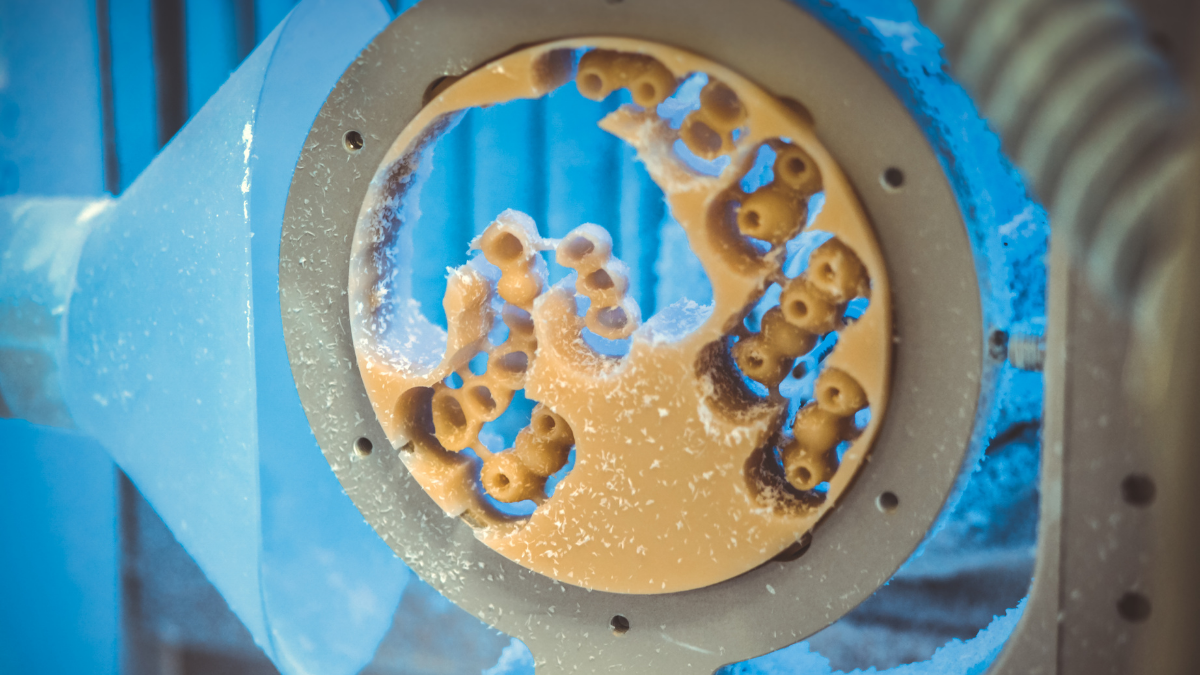

Modern dentistry needs materials that can do a lot of different things, like beautiful glass-ceramics and translucent multilayered zirconia, as well as strong metals like titanium and cobalt-chrome. A high-performance CAM dental fabrication machine, especially a hybrid model that can do both wet and dry milling, lets the lab work with all of these materials in-house.

Dry milling is best for quickly processing materials like PMMA and zirconia.

Wet milling is necessary for grinding glass-ceramics and metals with precision and heat control to keep the material intact and give it a great surface finish.

The lab can take on a wider range of cases because it can process a wider range of materials. This means it can handle different clinical needs and budgets without having to hire outside help for specialized work. This control over the supply chain for materials makes things run more smoothly and keeps profit margins safe.

Did You Know?

that a modern 5-axis dental milling machine can make a full-contour zirconia crown from a digital file in less than 15 minutes? This used to take a technician several hours over several days.

Strategic Financial Return and Competitive Edge

From a business point of view, a dental milling machine is a very important piece of equipment that helps make money. A strong return on investment (ROI) comes from being able to produce more without having to pay more for labor. Also, being able to offer shorter turnaround times (TATs) and better, repeatable quality restorations gives the lab a big edge over its competitors, allowing it to get and keep high-volume dental practice clients. Labs that use this technology strengthen their position as leaders in the digital dentistry ecosystem.

To stay competitive and make money in the changing world of dentistry, you have to use subtractive manufacturing technology. Advanced dental milling machines make it possible to produce more and keep the same level of quality by improving operational efficiency, accuracy, and the ability to work with a wider range of materials.

Contact Axsys Dental Solutions at (855) 687 7941 to schedule a consultation with a product specialist and explore the right Versamill solution for your business.

Frequently Asked Questions (FAQs)

What is the difference between 4-axis and 5-axis milling?

A 4-axis machine moves along X, Y, Z, and one rotational axis (A). A 5-axis machine adds a fifth rotational axis (B), allowing the tool to reach the restoration from more complex angles. The 5-axis system is preferred for complex geometries, undercuts, and superior margin-fitting on intricate restorations like implant abutments.

What is an ‘open’ milling system?

An open milling system is a machine that is compatible with design files (typically STL format) from virtually any third-party intraoral scanner or CAD software. This offers the laboratory maximum flexibility and avoids being locked into a single proprietary ecosystem.